Who is in charge of lithium ion batteries

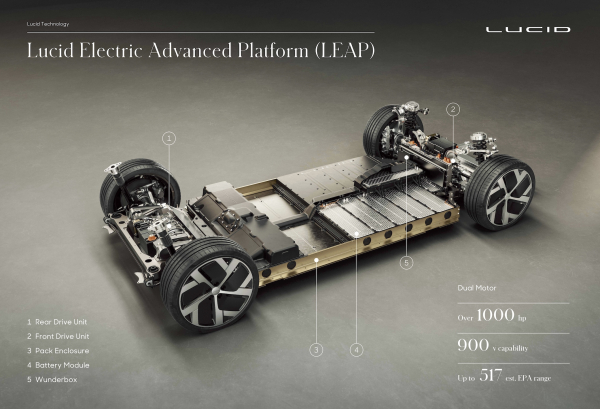

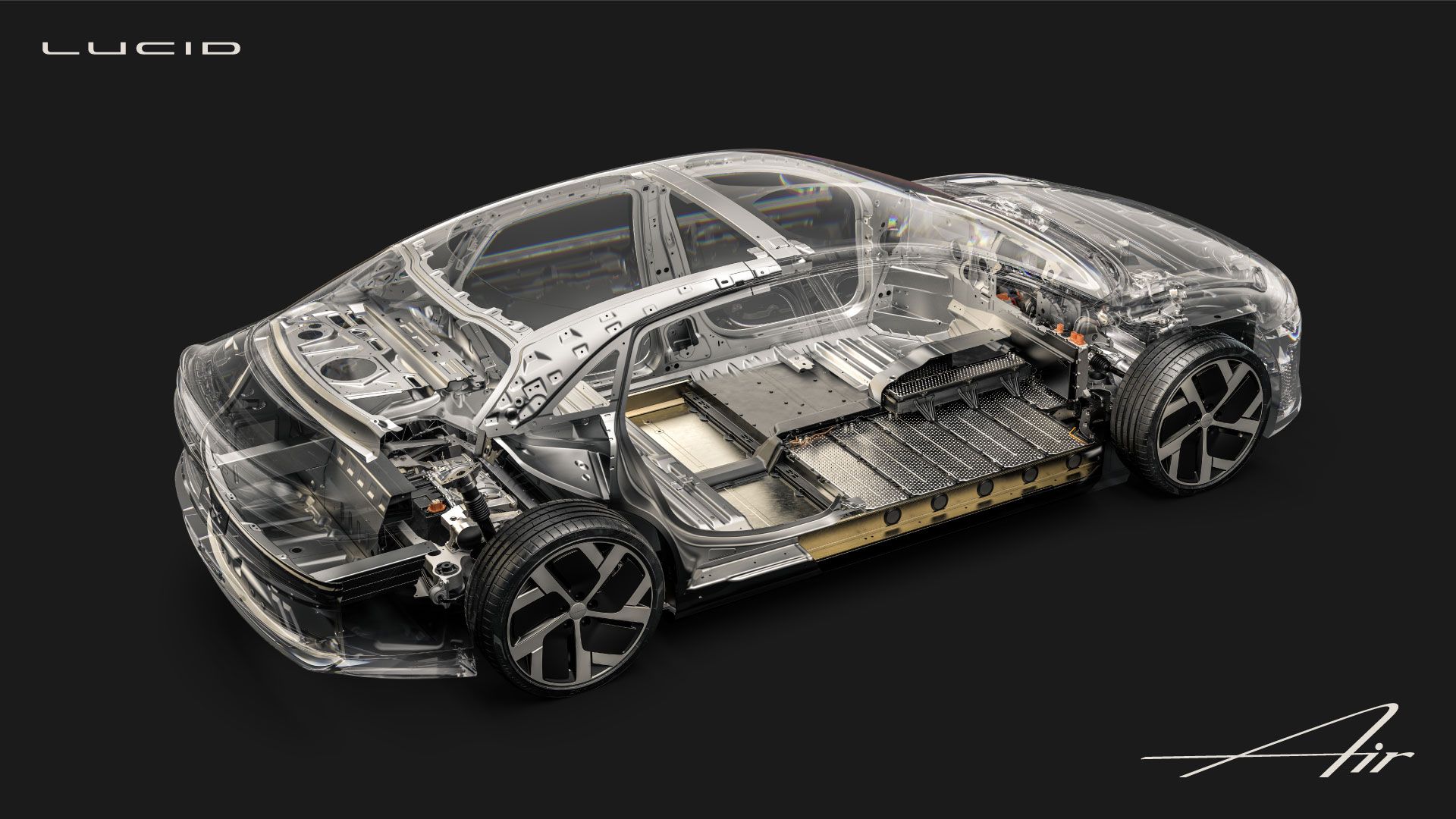

The key enabling component in electric and hybrid vehicles is the battery pack. Higher power density and lower lithium ion battery systems have changed the way we store and use power in vehicles. Back in the early days of electric cars, heavy lead-acid batteries were used, but they simply didn't have enough storage per unit mass to make a difference.

However, one type of battery that has a higher capacity and discharge rate is the lithium ion battery. However, lithium ion batteries present some major challenges, requiring a complex electronic control system called a battery management system, or BMS.

Lithium-ion batteries are relatively difficult to manage because their charge/discharge curves are very nonlinear. With lead-acid batteries, it is easy to determine the degree of charge by simply measuring its voltage, and there is a very straightforward way to determine the state of charge based on this information.

The role of the BMS

Lithium ion batteries may release high energy in the event of a major failure, so a safety mechanism is needed to prevent damage to lithium-ion batteries in the event of a short circuit. The most basic piece of equipment is a fuse that will break at high currents. Some fuses will blow permanently, deactivating the battery.

This protective circuit protects the battery from external damage, but cannot be stopped once the internal heat gets out of control. Like a nuclear meltdown, batteries run on their own energy, but some advanced batteries have built-in melt barriers that slow the process by inhibiting the flow of ions at high temperatures. The batteries recalled in 2006, as well as those used in the Boeing 787's power supply and other accidents, passed all regulatory safety requirements but failed in normal use and properly protected circuitry.

All in all, it can be seen that the Battery Management System (BMS) is a key part of the EV powertrain. Due to the charging/discharging characteristics and safety considerations of BMS, it is necessary to measure the charging state and condition of lithium battery. It performs a number of key functions to ensure maximum battery pack capacity, such as battery balancing and charger control

If you need help with lithium ion battery development, please do not hesitate to contact cyclenpo Technology directly.