Lithium-ion (Li-ion) batteries are often the battery of choice for mobile devices and off-grid products. Li-ion technology has a number of advantages over other battery chemistries including high energy density, excellent efficiency, competitive cost, and good cycle life. Lithium ion battery safety, however, is one issue that is a concern with battery systems. Under certain conditions, Liion batteries can catastrophically catch fire or explode, potentially starting fires or causing serious injury or death.

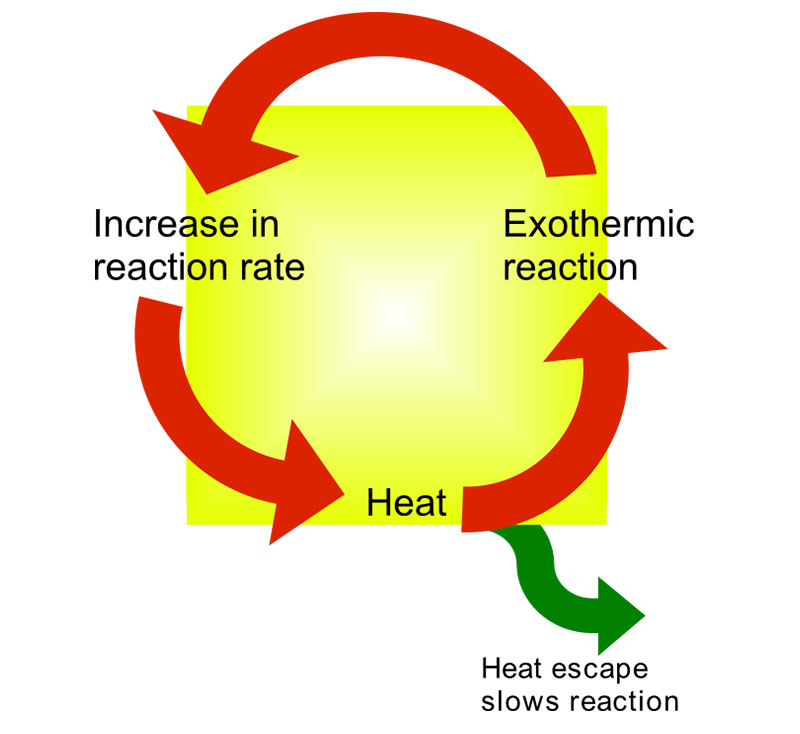

The primary hazard from Li-ion batteries is a catastrophic event called thermal runaway in which the battery quickly and sometimes violently releases is stored electrochemical energy. During thermal runaway, the internal temperature of the battery cell exceeds temperatures of 500°C as the internal components react and ignite. Flammable gasses are generated inside the case, which will build up pressure and vent (often with the gases on fire) or even explode if the pressure relief mechanisms don’t function properly. Depending on the size and design of the battery cell(s), cell cases, and battery pack, this can be extremely dangerous.

What causes thermal runaway

Several factors can lead to thermal runaway of a lithium-ion battery:

-Internal short circuit: Due to an accident or similar mechanical impact, e.g. if a tool falls down from a great height, the battery is deformed, material penetrates the battery cell and triggers an internal short circuit.

-External short circuit: Deformation of the battery cell causes an external short circuit.

-Overcharging the battery beyond the maximum voltage specified in the data sheet, e.g. to increase the range of an electric car. Depending on the degree of overcharging, the battery may be damaged permanently and the service life of the battery decreases.

-Excessive currents when charging or discharging the battery, e.g. when rapid charging.

How to prevent thermal runaway?

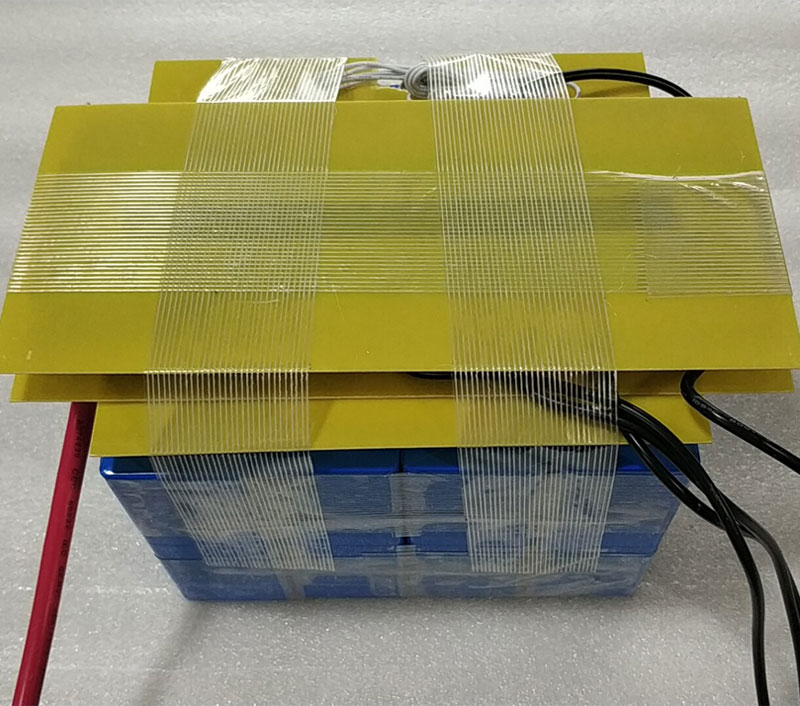

-Cell manufacture, capacity matching, and battery pack assembly

Safe Li-ion battery design starts in the battery factory and includes carefully controlled manufacturing processes, contamination-free cell assembly, proper conditioning, and good cell matching.The battery manufacturer should provide charge/discharge profiles, specific voltage and temperature limits, and cell output tolerances (capacity, voltage etc.) for the lot or cell type. Cells used in battery packs should always be of the same type and from the same manufacturer, preferably from the same manufacturing lot. Cell capacities should be matched as closely as possible so that all the cells experience approximately the same voltage and stateof-charge cycle history. Older or used cells should never be used with new cells

-Built-in cell protection and venting

Li-ion batteries are designed with safety features that can shut down the cell current and release pressure from gas buildup before the case ruptures catastrophically (explodes) and ejects burning electrolyte and molten cell contents.The most common and mature designs for venting are found in cylindrical cells, though battery manufacturers use a variety of designs. A positive temperature coefficient (PTC) switch is a conductive polymer disk that increases its electrical resistance with an increase in temperature. This decreases the current draw from the cell and is designed to reset when the temperature returns to normal. A current interrupt device (CID) is another disk that is designed to permanently disconnect the positive terminal with an increase in pressure and preferentially break to release that pressure.

-Safer battery materials

Many off-grid products use Lithium Iron Phosphate (LiFePO4, also abbreviated as LFP) for the cathode positive electrode. LiFePO4 batteries exhibit many qualities that make them ideally suited for solar applications where safety, stability, and cycle life are primary requirements.They have lower energy density than competing Li-ion chemistries, but this is acceptable for many off-grid applications. The key advantage of LiFePO4 as a cathode material lies in its chemical stability and the ability to withstand relatively high temperatures. The molecular structure absorbs and releases lithium ions without a large change in volume, and is resistant to the growth of defects from daily charge and discharge cycles. LiFePO4 cells are NOT impervious to thermal runaway, however, and the same precautions for other chemistries also apply to them.

-Battery management systems

Battery management systems must be used with Li-ion batteries to control charging and protect the individual cells from electrical abuse. High and low voltages, high charge currents, external short circuits, and proper charging profiles are necessary to protect Liion cells from electrical abuse and provide adequate cycle lifetimes. Li-ion batteries can be badly damaged from just a single electrical abuse event or from longer term smaller scale cyclical abuse.

Battery protection circuitry can be incorporated directly into the battery cell, cell block, or pack, OR it can be integrated with the off-grid product’s other control circuitry external to the battery. It must be capable of reliably regulating the battery within the specific tolerance range provided by the battery manufacturer.

Conclusions

Li-ion battery technologies, when properly deployed, are safe, cost-effective, durable, and well suited to off-grid applications. With certain lithium technologies under specific abuse conditions, however, they can enter thermal runaway and catastrophically release considerable amounts of energy in a very short amount of time. The resulting fire or explosions can be extremely dangerous to people and property.

Li-ion battery fires in consumer products, though rare, are high profile events that can cause significant harm and garner considerable attention. Understanding Li-ion hazards should be well understood by off-grid product manufacturers that use these technologies, and preventing catastrophic failures should be the highest priority for battery manufacturers and off-grid product manufacturers.