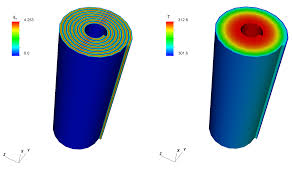

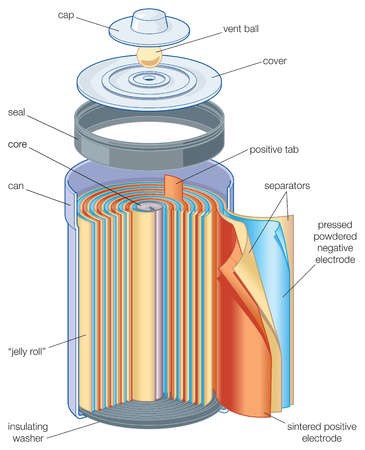

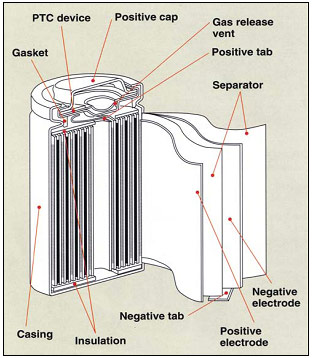

The cylindrical cell continues to be one of the most widely used packaging styles for primary and secondary batteries. The advantages are ease of manufacture and good mechanical stability. The tubular cylinder can withstand high internal pressures without deforming. The cylindrical cell design has good cycling ability, offers a long calendar life and is economical, but is heavy and has low packaging density due to space cavities.

Popular 18650 lithium-ion cell.

The metallic cylinder measure 18mm in diameter and 65mm the length. The larger 26650 cell measures 26mm in diameter.

Typical applications for cylindrical cells are power tools, medical instruments, laptops, and e-bikes. To allow variations within a given size, manufacturers use partial cell lengths, such as half and three-quarter formats, and nickel-cadmium provides the largest variety of cell choices.

Some spilled over to nickel-metal-hydride, but not to lithium-ion as this chemistry established its own formats. The 18650 illustrated remains one of the most popular cell packages. Typical applications for the 18650 Li-ion are power tools, medical devices, laptops, and e-bikes.

The cylindrical cell has high specific energy, good mechanical stability, and lends itself to automated manufacturing. Cell design allows added safety features that are not possible with other formats (see BU-304b: Making Lithium-ion Safe); it cycles well, offers a long calendar life, and is low cost, but it has less than ideal packaging density. The cylindrical cell is commonly used for portable applications.